In today’s technology-driven world, devices and machines are expected to be smarter, faster, and more reliable. At the center of this transformation lies the embedded control software system—a critical element that integrates hardware and software to deliver efficient, real-time control. From automobiles and industrial machinery to medical devices and household appliances, embedded control software systems are shaping the way we live and work.

What is an Embedded Control Software System?

An embedded control software system is a specialized program designed to manage and control the functions of hardware components within a larger system. Unlike general-purpose software, embedded software is dedicated to specific tasks and runs directly on microcontrollers or processors.

For example, in a modern washing machine, embedded control software manages the washing cycles, water levels, and spin speed. In automobiles, it controls engine performance, braking systems, and infotainment units. Its core strength lies in executing instructions in real time to ensure the system operates accurately and safely.

Key Components

Microcontrollers/Processors

The “brain” of the system, responsible for executing instructions.

Sensors

Gather real-world data, such as temperature, speed, or pressure.

Actuators

Perform physical actions, such as turning motors or adjusting valves, based on software commands.

Control Algorithms

Mathematical models like PID (Proportional-Integral-Derivative) regulate system behavior.

Communication Interfaces

Protocols like CAN, SPI, I2C, or Ethernet ensure smooth interaction between hardware components.

Development Process

Building an embedded control software system requires a structured approach:

Requirement Analysis

Understanding system needs such as performance, safety, and energy efficiency.

System Design

Planning hardware-software architecture to meet constraints like memory and processing power.

Modeling and Simulation

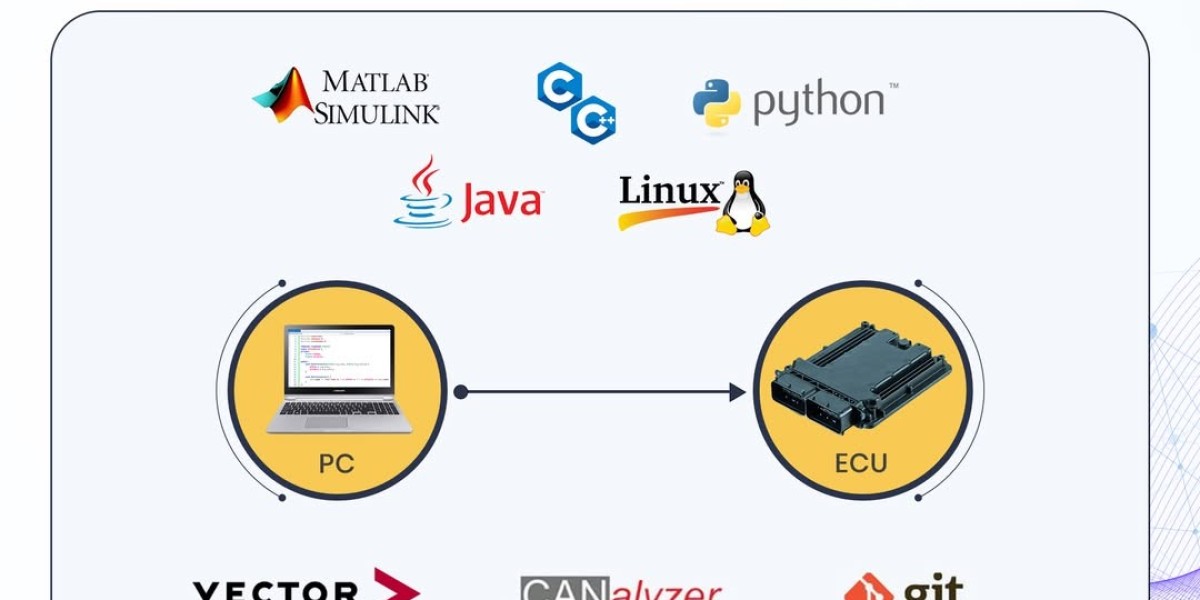

Tools like MATLAB/Simulink are used to model behavior and test algorithms virtually.

Software Development

Writing code in C, C++, or Python and integrating real-time operating systems (RTOS).

Integration with Hardware

Loading the software into microcontrollers and testing with actual sensors and actuators.

Validation and Testing

Using methods like Hardware-in-the-Loop (HIL) testing to ensure reliability.

Deployment and Optimization

Refining the system for performance, cost, and energy efficiency.

Applications Across Industries

Automotive:

Powers ECUs (Electronic Control Units), ABS, airbags, electric power steering, and driver-assistance systems.Consumer Electronics:

Runs devices such as refrigerators, microwaves, and smart TVs.Industrial Automation:

Controls robotics, CNC machines, and automated assembly lines.Healthcare:

Ensures safety in devices like ventilators, pacemakers, and infusion pumps.Aerospace and Defense:

Critical for avionics, drones, and navigation systems.Energy:

Used in solar inverters, wind turbines, and smart grids for efficient energy management.

Benefits of Embedded Control Software

Efficiency

Delivers precise control, reduces errors, and optimizes resource use.

Reliability

Built to handle mission-critical operations without failure.

Real-Time Operation

Responds instantly to events, such as airbag deployment during a crash.

Compact and Cost-Effective

Combines hardware and software into streamlined, cost-efficient solutions.

Scalability

Suitable for both simple consumer products and highly advanced industrial systems.

Challenges

Resource Constraints

Systems must operate within limited memory and processing power.

System Complexity

Integrating multiple components increases design difficulty.

Real-Time Demands

Many applications require millisecond-level response times.

Security

IoT connectivity raises risks of cyberattacks on embedded systems.

Testing and Validation

Ensuring accuracy and safety across all scenarios can be resource-intensive.

Future Trends

Artificial Intelligence Integration

Embedded AI will enable self-learning and adaptive systems.

Internet of Things (IoT)

More devices will connect and communicate, requiring stronger embedded systems.

Edge Computing

Processing closer to the source will reduce latency and improve speed.

Green and Sustainable Technologies

Energy-efficient designs will dominate industries like automotive and energy.

Advanced Simulation and Digital Twins

Virtual models will reduce development cycles and improve accuracy.

Conclusion

Embedded control software systems are the unseen powerhouses of modern technology. By integrating hardware and software in a seamless way, they deliver intelligence, speed, and reliability to countless applications—from daily-use appliances to mission-critical aerospace systems.

Their ability to process data in real time, enhance safety, and improve efficiency makes them indispensable in every industry. While challenges such as resource constraints, security, and testing remain, future innovations in AI, IoT, and edge computing will push embedded systems to new levels of performance.

As technology continues to advance, embedded control software systems will remain the cornerstone of intelligent, reliable, and sustainable solutions worldwide.