In today’s fast-paced technological era, the demand for intelligent, automated, and efficient systems has revolutionized industries. At the core of this transformation lies mechatronics and hardware design. By integrating mechanical engineering, electronics, computer science, and control systems, mechatronics creates smart products and solutions that combine physical hardware with intelligent software. Whether in robotics, automotive systems, healthcare, or industrial automation, mechatronics and hardware design play a critical role in shaping innovations that drive progress and improve everyday life.

What is Mechatronics?

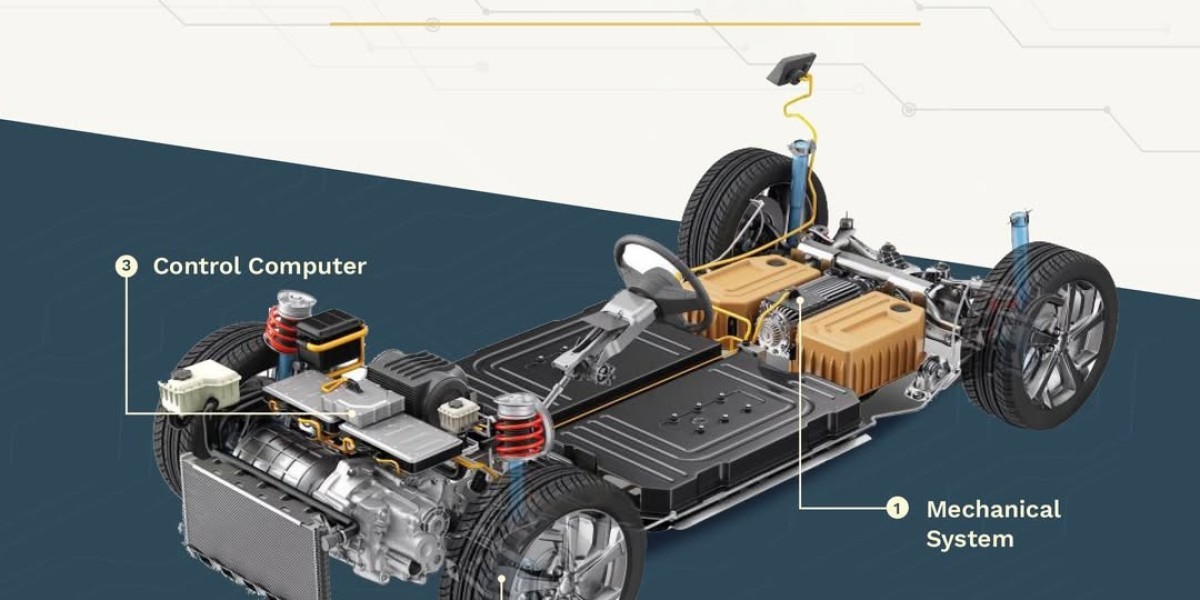

Mechatronics is a multidisciplinary field that merges mechanical engineering, electrical engineering, electronics, computer systems, and control engineering to design intelligent systems. Unlike traditional mechanical systems, mechatronic systems are designed to sense, process, and act in real-time. This integration allows engineers to build products that are not only functional but also adaptive, precise, and efficient.

Some common examples of mechatronics in action include:

Autonomous robots

Advanced driver-assistance systems (ADAS) in vehicles

CNC machines in manufacturing

Medical devices like robotic surgery systems

Smart home appliances

What is Hardware Design?

While mechatronics focuses on integrating multiple domains, hardware design is the foundation that enables these systems to function effectively. Hardware design involves creating physical components such as circuits, sensors, actuators, controllers, and processors that form the backbone of mechatronic systems.

Effective hardware design ensures that:

Sensors accurately capture environmental data.

Actuators respond with precision.

Microcontrollers and processors execute control algorithms efficiently.

Devices operate reliably under varying conditions.

Together, mechatronics and hardware design create systems that combine physical performance with digital intelligence.

The Role of Mechatronics and Hardware Design in Modern Engineering

Automation and Robotics

Mechatronics enables the development of autonomous robots that can perform repetitive, complex, or hazardous tasks with accuracy. Hardware design ensures these robots are equipped with the right sensors, actuators, and control boards to operate reliably.Automotive Industry

From engine management systems to electric vehicle battery management and ADAS features like lane-keeping assistance, mechatronics drives innovation. Hardware design ensures that the control units, communication interfaces, and sensor networks function seamlessly in demanding automotive environments.Healthcare and Medical Devices

Advanced diagnostic equipment, robotic-assisted surgery systems, and wearable health devices rely heavily on mechatronic principles and robust hardware design. These systems enhance patient care through precision and reliability.Industrial Automation

Smart factories and Industry 4.0 solutions use mechatronic systems for machine control, predictive maintenance, and real-time monitoring. Hardware design plays a critical role in ensuring that industrial sensors and controllers meet performance and safety standards.Aerospace and Defense

Mechatronics and hardware design support navigation systems, flight controls, unmanned aerial vehicles (UAVs), and mission-critical defense technologies, where precision and reliability are non-negotiable.

Benefits of Mechatronics and Hardware Design

Precision and Accuracy: Integrating sensors, actuators, and control algorithms ensures highly accurate and repeatable operations.

Efficiency: Mechatronic systems optimize energy and resource consumption, making processes more cost-effective.

Innovation: Combining hardware with smart software enables the creation of cutting-edge technologies.

Flexibility: Systems can be adapted for multiple applications across industries.

Reliability: Robust hardware design ensures long-lasting, fault-tolerant performance.

Challenges in Mechatronics and Hardware Design

Despite the numerous benefits, engineers face several challenges in developing advanced systems:

Integration Complexity

Bringing together mechanical, electronic, and software components requires deep expertise and precise coordination.Cost Constraints

High-end hardware components and advanced software tools often increase development costs.Miniaturization

Designing compact yet powerful hardware is a constant challenge, especially in consumer electronics and medical devices.Security and Safety

Systems must be designed to prevent cyber threats and ensure safe operation in critical applications.Rapid Technological Changes

Engineers must continuously update designs to keep pace with evolving technologies such as AI, IoT, and machine learning.

Tools and Technologies Supporting Mechatronics

CAD/CAE Tools: For mechanical and hardware design.

MATLAB/Simulink: For system modeling, simulation, and control design.

PCB Design Software: For creating efficient circuit boards.

IoT Platforms: For connectivity and remote monitoring.

AI and Machine Learning: For predictive decision-making and automation.

These tools empower engineers to design and validate mechatronic systems before deploying them in real-world environments.

Future Trends in Mechatronics and Hardware Design

Artificial Intelligence Integration

Future systems will integrate AI for smarter decision-making and adaptive control.Internet of Things (IoT)

Mechatronic devices connected through IoT will enable smarter homes, factories, and cities.Digital Twins

Virtual replicas of physical systems will be used to predict behavior and optimize performance.Sustainable Design

Hardware will be designed for energy efficiency and minimal environmental impact.Autonomous Systems

Robotics, drones, and self-driving vehicles will evolve with more advanced mechatronic architectures.

Conclusion

Mechatronics and hardware design are at the heart of technological progress, enabling the development of intelligent, efficient, and adaptive systems across industries. By merging mechanical engineering with electronics, computing, and control systems, engineers can create innovative solutions that transform industries such as automotive, healthcare, aerospace, and manufacturing.

Though challenges like integration complexity and rapid technological change remain, advancements in AI, IoT, and sustainable design are shaping a promising future. As industries embrace automation and digital transformation, mechatronics and hardware design will remain vital in creating the next generation of smart, connected, and reliable technologies.