In today’s highly competitive industrial landscape, businesses are under constant pressure to innovate faster, reduce costs, and deliver reliable products. Achieving these objectives requires robust design and analysis capabilities that go beyond traditional approaches. This is where CAD and FEA engineering services play a critical role. Together, these tools empower engineers and organizations to conceptualize, model, analyze, and optimize products before physical prototypes are ever built.

Understanding CAD Engineering Services

Computer-Aided Design (CAD) refers to the use of software applications to create detailed 2D drawings and 3D models of products, components, or systems. CAD has become an essential engineering tool across industries such as automotive, aerospace, manufacturing, consumer electronics, energy, and healthcare.

Key capabilities of CAD services include:

3D Modeling and Visualization – Engineers can build accurate digital models that represent real-world components with high precision. This enables teams to visualize the product in different environments, detect potential issues, and make early design improvements.

Parametric Design – CAD systems allow changes in parameters such as dimensions, materials, and tolerances, ensuring flexibility and reducing rework.

Assembly Modeling – CAD services enable engineers to visualize how parts will fit and interact within larger assemblies, helping to identify potential interferences or alignment issues.

Detailed Drawings and Documentation – Accurate 2D drawings, bills of materials, and manufacturing instructions are generated directly from CAD models, reducing errors in production.

Product Lifecycle Integration – CAD designs can be integrated with Product Lifecycle Management (PLM) and Enterprise Resource Planning (ERP) systems, creating a seamless workflow from concept to manufacturing.

Overall, CAD engineering services streamline product development, enhance collaboration, and reduce the time required to move from design to production.

Understanding FEA Engineering Services

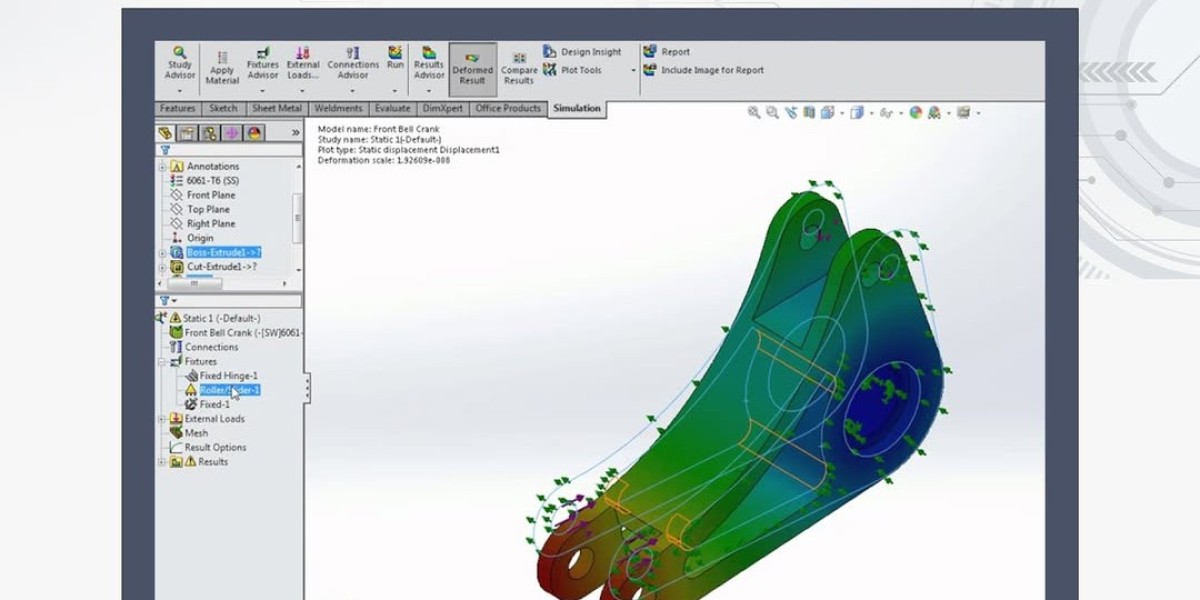

While CAD provides a virtual representation of a design, Finite Element Analysis (FEA) goes a step further by simulating how the product will perform under real-world conditions. FEA is a numerical method used to analyze the structural, thermal, fluid, and dynamic behavior of a product or system.

Key capabilities of FEA services include:

Structural Analysis – Determines stress, strain, and deformation of materials under various loads. This is crucial for ensuring safety and durability.

Thermal Analysis – Evaluates how heat transfer and temperature variations affect product performance, which is vital in industries such as electronics, automotive, and energy.

Modal and Vibration Analysis – Identifies natural frequencies and vibration modes to prevent resonance issues in mechanical systems.

Fatigue and Failure Prediction – Predicts the lifespan of a component under repeated loading, helping engineers design products with higher reliability.

Fluid Flow Analysis (CFD Integration) – When coupled with Computational Fluid Dynamics (CFD), FEA provides insights into fluid-structure interactions, making it useful in aerospace, automotive, and biomedical applications.

By using FEA engineering services, organizations can significantly reduce the need for costly physical prototypes, optimize material usage, and ensure products meet safety and regulatory standards.

Benefits of Integrated CAD/FEA Engineering Services

When CAD and FEA are integrated, businesses gain a powerful combination of design and validation tools. This integration allows for continuous design improvements during the development process, ensuring that final products are not only visually appealing but also structurally sound and efficient.

Some of the major benefits include:

Reduced Development Time – Virtual testing eliminates the need for multiple physical prototypes, accelerating time-to-market.

Cost Savings – By identifying design flaws early, companies can avoid expensive redesigns and manufacturing errors.

Enhanced Product Performance – Engineers can test multiple design iterations and optimize products for strength, weight, efficiency, and durability.

Innovation and Customization – CAD/FEA services provide flexibility to experiment with new ideas and customized solutions without increasing development risks.

Regulatory Compliance – With FEA validation, designs can meet industry standards and certifications more efficiently.

Applications Across Industries

CAD/FEA engineering services are widely applied across multiple industries:

Automotive – Used for crash simulations, chassis design, thermal management, and aerodynamics optimization.

Aerospace – Supports lightweight structures, fatigue testing, vibration analysis, and aerodynamic simulations.

Manufacturing – Helps in tooling design, sheet metal forming analysis, and structural integrity of machinery.

Electronics – Ensures thermal stability of circuit boards and enclosures.

Medical Devices – Provides detailed stress analysis for implants, surgical instruments, and prosthetics.

Energy Sector – Optimizes performance of wind turbine blades, pressure vessels, and pipelines.

These services ensure that products meet stringent performance requirements while remaining cost-effective.

Why Outsource CAD/FEA Engineering Services?

Many companies choose to partner with specialized CAD/FEA service providers instead of handling everything in-house. Outsourcing provides several advantages:

Access to Expertise – Service providers employ experienced engineers with expertise across domains.

Advanced Tools and Technologies – They utilize the latest CAD and FEA software, ensuring high-quality results.

Scalability – Businesses can scale services based on project needs without maintaining large in-house teams.

Cost Efficiency – Outsourcing reduces overhead costs related to software licensing, training, and infrastructure.

Focus on Core Business – Companies can focus on strategic functions while leaving design and analysis tasks to experts.

Future of CAD/FEA Engineering Services

With advancements in artificial intelligence (AI), machine learning, cloud computing, and digital twins, the future of CAD/FEA looks even more promising. AI-driven design optimization will enable engineers to explore thousands of design alternatives quickly. Cloud-based FEA will provide scalable simulation capabilities, while digital twin technology will create real-time virtual models of physical products for continuous monitoring and improvement.

Conclusion

CAD/FEA engineering services are the backbone of modern product development, offering a blend of creativity, precision, and validation. By integrating advanced design and analysis tools, businesses can reduce costs, accelerate innovation, and deliver high-performance products with confidence. Whether in automotive, aerospace, healthcare, or energy, these services continue to reshape industries and empower organizations to stay ahead in a competitive world.