Embedded control development is at the heart of modern engineering, powering everything from automotive systems and industrial machinery to consumer electronics and medical devices. As technology continues to advance, embedded control systems are becoming increasingly complex, requiring more sophisticated hardware and software solutions to ensure high performance, reliability, and efficiency. This article explores the fundamentals of embedded control development, its significance, applications, challenges, and future directions.

Understanding Embedded Control Development

Embedded control development refers to the process of designing, programming, testing, and optimizing control systems that are embedded within larger devices or machines. These systems integrate hardware (microcontrollers, sensors, actuators, and communication interfaces) with software (control algorithms, operating systems, and application code) to achieve specific functionalities.

Unlike general-purpose computers, embedded control systems are application-specific, meaning they are tailored to perform dedicated tasks such as managing engine performance, regulating robotic movements, or controlling smart home appliances. The development process combines principles of control engineering, electronics, and computer science, making it a highly interdisciplinary field.

Key Components of Embedded Control Systems

Microcontrollers and Processors

The core of any embedded control system is the microcontroller or processor. These are compact computing units optimized for real-time control tasks. They execute control algorithms, process sensor data, and send signals to actuators.Sensors and Actuators

Sensors collect real-world data such as temperature, pressure, motion, or voltage. Actuators, on the other hand, convert digital control signals into physical actions, such as rotating a motor, opening a valve, or adjusting light intensity.Control Algorithms

Embedded systems rely on mathematical control algorithms, such as PID (Proportional-Integral-Derivative), adaptive control, or model-based design approaches, to ensure the system performs accurately and efficiently.Communication Interfaces

Many systems use communication protocols like CAN (Controller Area Network), I2C, SPI, or Ethernet to connect subsystems and ensure seamless data exchange.Software and Firmware

Embedded control development involves writing firmware and application code to manage system behavior, implement algorithms, and provide user interfaces.

The Development Process

Embedded control development typically follows a structured workflow that ensures robust design and efficient implementation:

Requirement Analysis

The process begins with defining the system’s requirements, including performance goals, cost constraints, safety standards, and energy efficiency needs.System Design

Engineers design the architecture, choosing appropriate microcontrollers, sensors, and actuators. Control strategies are also formulated during this stage.Modeling and Simulation

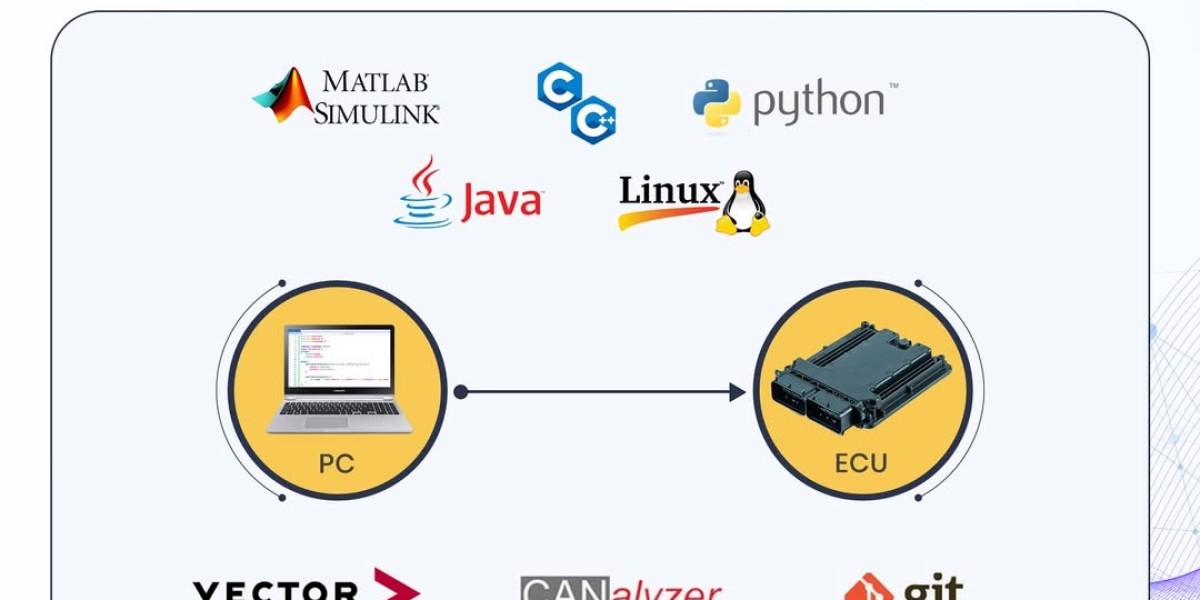

Advanced tools like MATLAB/Simulink are used to model system dynamics and simulate control strategies before hardware implementation. This reduces design risks and accelerates development.Software Development

Control algorithms and firmware are implemented using languages such as C, C++, or Python. Real-time operating systems (RTOS) may also be integrated for multitasking and scheduling.Hardware Implementation

The chosen hardware components are integrated into prototypes, with careful attention to power management, circuit design, and signal conditioning.Testing and Validation

Rigorous testing is performed using methods like Hardware-in-the-Loop (HIL) simulation, unit testing, and field testing. This ensures that the embedded system meets functional, safety, and reliability standards.Optimization and Deployment

The final stage involves refining performance, minimizing power consumption, reducing costs, and preparing the system for mass production.

Applications of Embedded Control Development

Embedded control development plays a vital role across multiple industries:

Automotive Industry: Used in engine control units (ECUs), advanced driver-assistance systems (ADAS), braking systems, and electric vehicle powertrains.

Industrial Automation: Controls robotics, conveyor systems, CNC machines, and process control systems for efficient manufacturing.

Consumer Electronics: Powers devices such as washing machines, smart thermostats, cameras, and smartphones.

Healthcare: Enables critical medical equipment such as ventilators, insulin pumps, and diagnostic devices.

Aerospace and Defense: Used in avionics, unmanned aerial vehicles (UAVs), and weapon control systems.

Renewable Energy: Controls wind turbines, solar inverters, and smart grids to maximize energy efficiency.

Challenges in Embedded Control Development

Despite its widespread use, embedded control development faces several challenges:

Complexity of Systems

As systems become more interconnected and multifunctional, developers must manage increasing complexity without compromising reliability.Real-Time Requirements

Many applications, especially in automotive and aerospace, require strict real-time performance. Meeting timing constraints is a major challenge.Power Efficiency

With the rise of portable and battery-powered devices, minimizing energy consumption while maintaining performance is critical.Safety and Security

Cybersecurity threats and safety-critical operations demand secure and fail-safe embedded systems, requiring robust protection mechanisms.Rapid Technological Change

Continuous advancements in processors, sensors, and communication protocols mean that developers must constantly update their skills and tools.

Future of Embedded Control Development

The future of embedded control development is shaped by emerging technologies and evolving industry needs:

Artificial Intelligence (AI) Integration: AI-driven control systems will enable predictive maintenance, adaptive decision-making, and smarter automation.

Internet of Things (IoT): Embedded systems are becoming increasingly connected, enabling remote monitoring, data analytics, and cloud-based control.

Edge Computing: Processing data at the edge rather than relying solely on the cloud will improve latency, reliability, and privacy in embedded applications.

Electrification and Sustainability: With the rise of electric vehicles and renewable energy systems, embedded controls will play a key role in optimizing energy efficiency and sustainability.

Advanced Simulation Tools: The use of digital twins and high-fidelity simulations will make design cycles faster and more cost-effective.

Conclusion

Embedded control development is the backbone of modern engineering, enabling intelligent and efficient operation across industries. By combining hardware, software, and control theory, it delivers solutions that meet real-time demands, improve safety, and enhance performance. While challenges such as complexity, security, and power efficiency remain, the field continues to evolve rapidly with AI, IoT, and advanced modeling tools. As technology advances, embedded control development will remain a cornerstone of innovation, driving smarter, safer, and more sustainable systems worldwide.