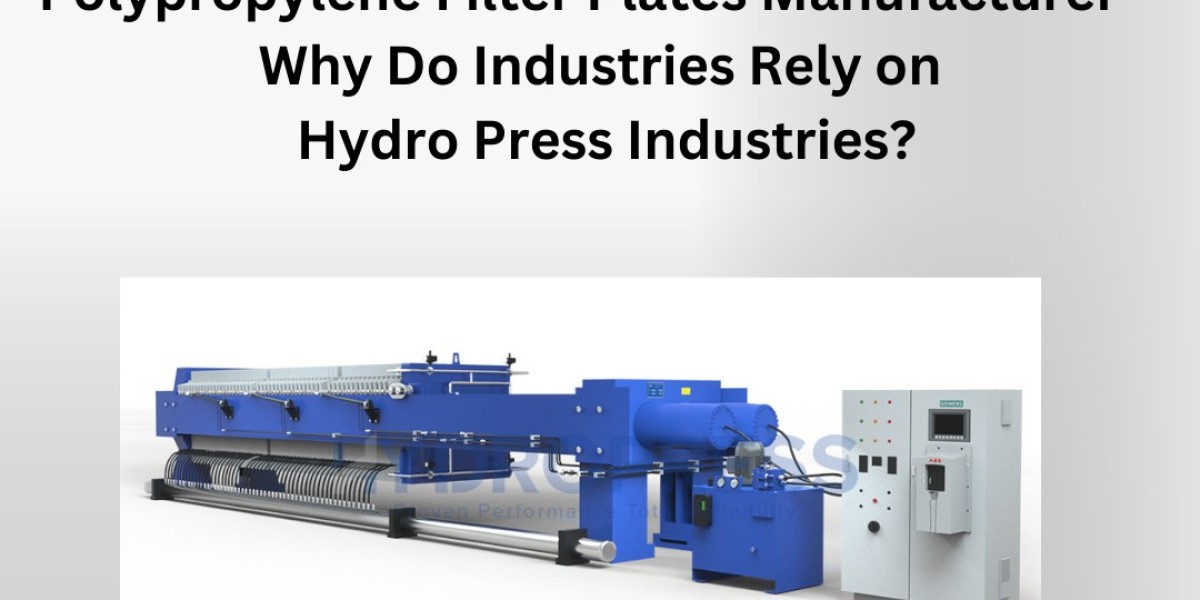

We at Hydro Press Industries have established ourselves as a trusted and performance-driven Polypropylene Filter Plates manufacturer, delivering precision-engineered solutions for demanding industrial filtration applications. Our commitment to quality, innovation, and reliability has positioned us as a preferred partner for industries that require consistent solid-liquid separation, long service life, and high chemical resistance.

Our Polypropylene Filter Plates are a critical component of modern filtration systems, and we manufacture them to meet global standards while exceeding customer expectations. From design to delivery, every stage of our production process is optimized to ensure strength, accuracy, and durability.

Why Polypropylene Filter Plates Are Essential for Industrial Filtration

Polypropylene filter plates are widely used across industries due to their excellent chemical resistance, lightweight structure, and high mechanical strength. These plates are integral to filter presses used in effluent treatment plants, chemical processing, pharmaceuticals, food and beverage, dyes, pigments, mining, and metallurgy.

We manufacture plates that offer:

Superior resistance to acids, alkalis, and solvents

High-pressure tolerance under continuous operation

Consistent filtration performance

Long operational life with minimal maintenance

Our polypropylene filter plates ensure reliable filtration even in aggressive operating environments, making them an indispensable choice for industrial users.

Advanced Manufacturing Capabilities at Hydro Press Industries

As a reputed Polypropylene Filter Plates manufacturer, we operate with advanced molding technologies and stringent quality control protocols. Our plates are produced using high-grade polypropylene raw materials that deliver exceptional dimensional stability and structural integrity.

Our manufacturing advantages include:

Precision injection molding for uniform thickness

Smooth filtration surfaces for effective cake release

Accurate plate alignment to prevent leakage

Customizable designs for specific filter press models

Each filter plate undergoes rigorous inspection to ensure it meets performance and safety benchmarks before dispatch.

Comprehensive Range of Polypropylene Filter Plates

We offer a wide range of polypropylene filter plates designed to suit various filtration needs and press configurations. Our portfolio includes plates suitable for both recessed chamber and membrane filter press systems.

Our range covers:

Recessed chamber filter plates

Membrane filter plates

Customized plate sizes and designs

High-pressure filter plates for heavy-duty applications

By offering customized filter press solutions, we help industries achieve optimal filtration efficiency while minimizing downtime and operational costs.

Unmatched Quality Standards and Material Excellence

Quality is central to our manufacturing philosophy. As a leading Polypropylene Filter Plates manufacturer, we follow strict material selection and testing procedures to ensure consistency and reliability.

Key quality features include:

High-impact polypropylene material

Excellent thermal and chemical stability

Uniform pore distribution for effective filtration

Robust construction to withstand cyclic pressure loads

Our filter plates maintain performance integrity even after prolonged exposure to harsh chemicals and repetitive filtration cycles.

Applications Across Diverse Industrial Sectors

Our polypropylene filter plates are engineered to support a wide spectrum of industries that demand efficient and dependable filtration systems.

Industries we serve include:

Effluent Treatment Plants (ETP & STP)

Chemical and petrochemical processing

Pharmaceutical manufacturing

Food and beverage processing

Dyes, pigments, and intermediates

Mining, minerals, and metallurgy

Each application benefits from our plates’ ability to deliver consistent filtration results with minimal operational disruption.

Customized Filtration Solutions for Specific Needs

We understand that filtration requirements vary across industries. That is why we specialize in customized polypropylene filter plates tailored to specific operating parameters such as pressure, temperature, slurry characteristics, and filtration cycle time.

Our customization capabilities ensure:

Perfect compatibility with existing filter presses

Optimized filtration efficiency

Reduced wear and tear

Enhanced productivity

By working closely with our clients, we deliver solutions that align precisely with their operational objectives.

Commitment to Innovation and Process Optimization

Innovation drives our continuous growth as a Polypropylene Filter Plates manufacturer. We consistently invest in research, tooling upgrades, and process enhancements to improve product performance and longevity.

Our focus areas include:

Improved plate design for higher throughput

Enhanced surface finish for easy cake discharge

Optimized flow paths for uniform filtration

Reduced energy consumption during press operation

This commitment ensures that our products remain competitive and future-ready.

Reliable Supply, Timely Delivery, and Technical Support

We believe that product excellence must be supported by dependable service. Our production planning and logistics systems ensure the timely delivery of polypropylene filter plates without compromising quality.

Our customers benefit from:

Consistent product availability

Short lead times

Responsive technical assistance

Long-term service partnerships

Our team remains available to support installation, troubleshooting, and performance optimization throughout the product lifecycle.

Why Hydro Press Industries Is the Preferred Manufacturer?

Choosing the right Polypropylene Filter Plates manufacturer directly impacts filtration efficiency, operational reliability, and overall plant performance. We stand out due to our technical expertise, manufacturing precision, and customer-focused approach.

Key reasons to choose us:

Proven industry experience

High-performance polypropylene filter plates

Custom-engineered solutions

Strict quality control standards

Trusted by industries worldwide

Our solutions are designed not just to meet requirements, but to deliver measurable value over time.

Driving Efficiency Through Superior Filtration Technology

We continue to set new standards in industrial filtration by delivering polypropylene filter plates that combine strength, precision, and reliability. Our products help industries achieve cleaner output, reduced waste, and improved process efficiency.

With a focus on long-term performance and operational excellence, Hydro Press Industries remains the benchmark name in polypropylene filter plate manufacturing.

For more info visit - https://hydropressindustries.com/

Hydro Press Industries

SF no: 378/3, 279/1, PO, Ganesh Nagar, Malumichampatti, Tamil Nadu 641050

093448 35880

nisha@hydropressindustries.com

https://maps.app.goo.gl/BAtgssjq8BZrJ4ht8