By identifying potential weaknesses in packaging, this tester helps businesses prevent damage and reduce returns due to packaging failures. In this article, we will explore the features, benefits, and applications of the Drop Tester and why it is a must-have tool for industries that prioritize product protection.

Understanding the Working Principle of a Drop Tester

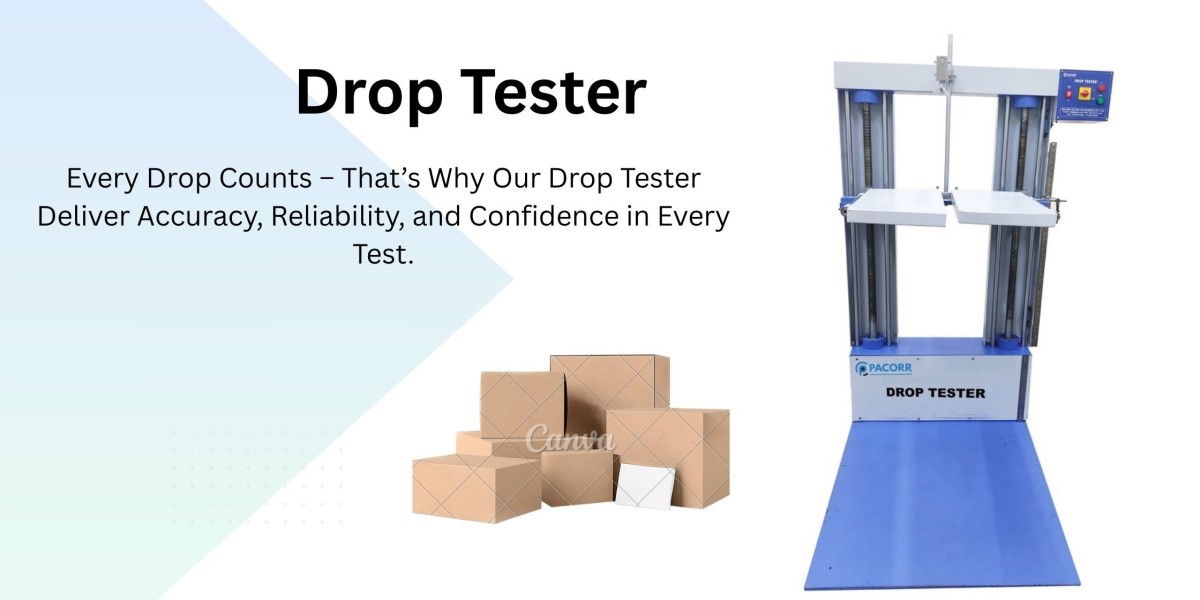

A Drop Tester is engineered to replicate the physical conditions that packaging may encounter during shipping and handling. The process involves dropping a sample—usually a box or a packaging material— from a predefined height onto a hard surface. The tester measures the force and impact energy on the material to determine how well it can withstand such events. The test provides critical data on whether the packaging can endure the rigors of logistics and protect the product inside.

Pacorr’s Drop Tester provides precise control over test conditions, allowing for adjustable drop heights, surface types, and test cycles. This flexibility ensures that the testing process can closely mimic real-life conditions, giving you reliable results that improve packaging decisions.

Top Benefits of Using a Drop Tester

Enhanced Product Protection

Testing packaging materials with the Drop Tester ensures that products are adequately protected during transit. By identifying weak spots in the packaging design, manufacturers can make improvements to prevent damage and enhance the overall safety of the product.Cost Savings

Investing in the Drop Tester can save businesses from costly losses caused by damaged goods. By preventing packaging failures, companies can reduce product returns, minimize insurance claims, and improve customer satisfaction.Compliance with Industry Standards

Various industries, including the pharmaceutical, food and beverage, and electronics sectors, are subject to strict packaging standards. Using a Drop Tester ensures that your packaging complies with the required regulations and safety standards, reducing the risk of non-compliance penalties.Optimized Packaging Design

The data provided by the Drop Tester helps packaging designers create more robust and cost-efficient packaging. By testing various materials and configurations, companies can identify the most effective designs for their products.Increased Customer Satisfaction

Quality packaging that minimizes damage during transit leads to higher customer satisfaction. When your products arrive intact, your brand earns a reputation for reliability, which can drive customer loyalty and positive reviews.

Should You Invest in a Drop Tester?

If your business relies on packaging to protect products during distribution, the answer is yes. The Drop Tester is an invaluable tool for any company involved in shipping products. Whether you are in e-commerce, retail, or manufacturing, testing your packaging will save you time, money, and customer dissatisfaction in the long run.

Additionally, by conducting regular tests, you ensure that your packaging remains robust even as packaging materials evolve or when new suppliers are involved. Investing in Pacorr’s Drop Testing helps future-proof your packaging processes against unexpected issues that could impact your bottom line.

Final Thoughts on Using a Drop Tester

The Drop Tester from Pacorr is more than just a tool—it is an investment in your packaging quality and overall product safety. With its precise testing capabilities, it helps businesses enhance the resilience of their packaging, ensuring products arrive in perfect condition. Whether you are dealing with fragile goods or bulk items, the Drop Tester provides the insight needed to make informed decisions about packaging materials and designs.

If you are ready to optimize your packaging testing process and improve product protection, visit pacorr.com for more information on the Drop Tester and how it can benefit your business.

FAQ Section:

1. What is a Drop Tester used for?

A Drop Tester is used to simulate the impact conditions that packaging materials endure during shipping, helping companies evaluate their durability and design improvements to prevent damage to the products inside.

2. Why is Drop Testing important for packaging?

Drop testing ensures that your packaging can withstand the rough handling it may experience during transportation, reducing the risk of damage, returns, and customer dissatisfaction.

3. Can the Drop Tester be adjusted for different drop heights?

Yes, the Drop Tester from Pacorr allows for customizable drop heights and surface types, making it versatile for testing different packaging materials and products.

4. How does the Drop Tester improve customer satisfaction?

By ensuring your packaging is durable and protective, the Drop Tester Price helps prevent damage during shipping, leading to fewer product returns and a better customer experience.

5. Is the Drop Tester compliant with industry standards?

Yes, Pacorr’s Drop Tester meets the required safety and testing standards, ensuring that your packaging is compliant with industry regulations.